SyBridge On-Demand

Digital Manufacturing Without Design Limitations

Instant Quotes for Injection Molding, CNC Machining & 3D Printing

SyBridge On-Demand is your one-stop digital manufacturing platform for injection molding, CNC machining and 3D printing. Simply upload your CAD/STEP/STL files to get instant manufacturing quotes across processes — including injection molding — and submit your order. It’s that easy.

Whether you’re a business owner, product owner or product design engineer, SyBridge On-Demand provides the instant access you need to enterprise-grade manufacturing technologies and materials to make parts and products for any application.

Create Your Free SyBridge On-Demand Account Today

Collaborative Engineering & Dedicated Support

Need help refining your product designs for improved quality or manufacturability?

Want to know the best manufacturing process or material for your product?

Ready to discuss volume production and product lifecycles?

We’re here to help.

Our team of engineers are experienced in product design and manufacturing across industries for every stage of the product lifecycle. From prototyping to production, questions big or small, we’re here to help you turn your great ideas into great parts and products.

Speak With an Expert Today

How Does SyBridge On-Demand Work?

Upload

Upload your CAD file in its native format and choose your manufacturing process and materials.

Quote

Experience AI-driven instant quoting and accurate lead times.

Order

Place your order, selecting desired quantities and shipping times.

With just a few clicks, you can turn your 3D digital designs (native CAD, STEP or STL files) into quality parts and products via injection molding, CNC machining or 3D printing.

Watch this short walkthrough to find out how SyBridge On-Demand works.

Then create your FREE account to get started.

Manufacturing Processes for Any Product or Production Volume

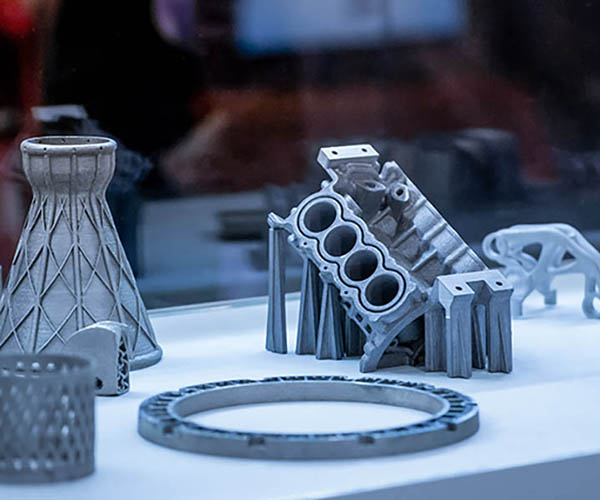

SyBridge On-Demand offers four unique 3D printing technologies that you can use to make custom parts and products quickly and cost-effectively from a variety of materials. And with CNC machining and injection molding, you can expand your design and material options and seamlessly increase production volumes to reduce per-unit costs and improve your margins.

Learn more about our manufacturing processes — explore all the options available in Sybridge On-Demand.

Injection Molding

CNC Machining

3D Printing

Experience On-Demand Digital Manufacturing Without Design Limitations

As a company filled with other product design engineers, we know the joy and the challenges of making something new and unique. Even if you’re an experienced product owner or designer, finding the right company to manufacture your products the way you want — and with the quality you expect — is no simple task. And it becomes even more challenging when you move beyond custom one-off products or small production runs to manufacturing the quantities you need to scale a product line or business.

But that’s why we’ve created SyBridge On-Demand, to give you access to scalable enterprise-grade manufacturing technologies without the hassle of multiple suppliers or complex quoting processes, backed by engineers with decades of experience.

Discover what SyBridge On-Demand can help you make — upload your CAD/STEP/STL design files and get started today!